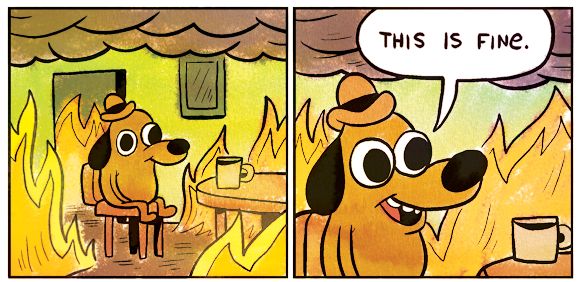

Recently, I spoke with the Supply Chain VP at a medical supply distributor who confidently said, “we don’t need to measure the state of our inventory; we just adjust our plan when something goes wrong.” His team would tweak a few SKUs each month to address whatever issues that came up, believing that this reactive approach was enough to manage their inventory effectively.

This mindset highlights a common challenge: many organizations rely on quick fixes instead of understanding the root causes of their inventory issues. Without a clear view of inventory health, even minor disruptions can escalate into significant problems, affecting service levels, increasing costs, and compromising overall business resilience.

So, what is inventory health, and why does it matter?

Inventory health is achieving the optimal balance between maintaining sufficient buffer and minimizing waste. Inventory health goes beyond merely having enough stock; it’s about dynamically managing stock levels to align with real-time demand, market shifts, and supply chain disruptions. Here are 6 reasons why it’s essential for businesses today:

1. Avoids Understocking and Overstocking

Traditional inventory management relies on static metrics like reorder points or safety stock levels. However, true inventory health requires a dynamic approach that constantly adjusts stock based on real-time data and market conditions. Aligning inventory with demand helps avoid the pitfalls of overstocking, which ties up capital and increases costs, and understocking, which can lead to stockouts and lost sales.

2. Enables Strategic Decision-Making in Complex Environment

In today’s interconnected supply chains, inventory health is key to navigating complexity. A healthy inventory system enables rapid adjustments to inventory levels based on fluctuations in both supply and demand across multiple geographies, suppliers, and distribution channels. This built-in agility allows for more strategic decisions, such as where to position inventory to mitigate risks associated with supply chain disruptions or geopolitical tensions, improving overall agility.

3. Drives Profitability Beyond Cost-Cutting

Rather than merely focusing on reducing costs, healthy inventory management contributes to profitability by maximizing product availability in high-demand periods and minimizing excess stock during slow periods. By precisely managing inventory turnover and aligning it with consumer demand patterns, companies can capture more sales opportunities and reduce the need for deep discounting to offload excess inventory.

4. Increases Supply Chain Resilience

A true understanding of inventory health provides forward-looking insights that go beyond historical data analysis. It enables businesses to anticipate market shifts, demand spikes, or potential supply chain disruptions by using predictive analytics and scenario planning. This allows decision-makers to create more resilient supply chain strategies that are prepared for multiple contingencies.

5. Minimizes Environmental and Operational Risks

Inventory health also plays a critical role in sustainability. Beyond reducing waste, maintaining optimal inventory levels minimizes the environmental impact of overproduction, excess transportation, and storage energy use. Moreover, healthier inventory practices help prevent operational risks like product spoilage, damage, or obsolescence, which can have significant financial and reputational consequences.

6. Builds a Competitive Advantage

In a world where supply chain disruptions are increasingly common, businesses that prioritize inventory health can better absorb shocks and maintain service levels. By maintaining healthy inventory, companies can not only avoid disruptions but also exploit opportunities more quickly than competitors, gaining a first-mover advantage in rapidly changing markets.

Inventory Health: The Key to Your Sustainable Business

Inventory health is about balance—ensuring the right products are available at the right time without incurring unnecessary costs or risks. In today’s rapidly changing market landscape, maintaining good inventory health is not just a best practice; it’s a competitive necessity.